Core shaft

Fixed mandrel, different structure, different force, different gear coordination.Installation methods are also different.Generally there are two kinds of fit: sliding fit and interference fit.Slip fit: for example, slip gear, aim the shaft at the position and Angle and push it in gently.Interference fit: when the interference amount is small, hammer can be used to hit the shaft end to drive the shaft.Before striking, cover the shaft end with other objects to prevent the shaft end from being damaged.

Large amount of interference, can be used to press the shaft.If there is no hydraulic press, with the help of some steel plates at hand, large bolts and so on, quickly make a temporary tool, with the help of screw force increase the role of the shaft into or push into gear.

Large interference: can be used heating method (eddy current heating and other ways), gear thermal expansion, can easily push the shaft, or in turn the shaft cooling contraction, and then push in.

Either way, remove burrs, dirt, and lube before assembly.

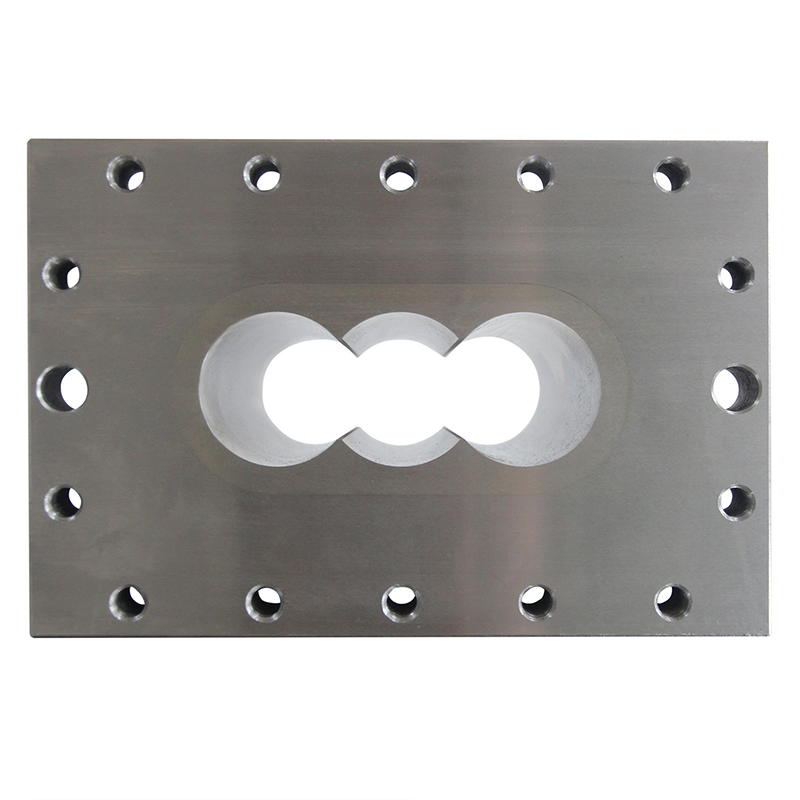

Barrels

Using machining center finishing, reasonable processing technology, advanced testing equipment, to ensure that the processing accuracy of each product.

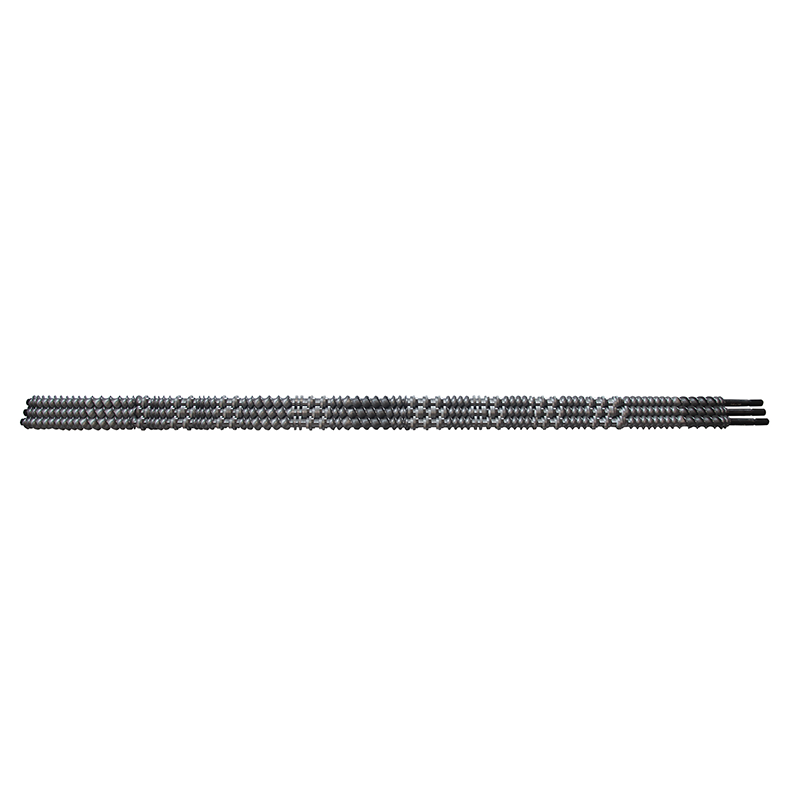

Twin-screw extruder screw element:

- convenient interchangeability by agile combination.

- fulfill efficient self-cleaning, transmission, compounding, pressure-forming and etc.

- made of high tool speed W6Mo5Cr4V2, or anti-corrosion steel 38CrMoAlA by speed treatment.

The flexible modular principle is realized with screw barrel sections from the wide range of different designs possible. Fast, intensive and uniform heating of the screw barrel section is ensured by electrical heaters. The barrel sections are cooled with water by means of an internal bore system with bores arranged close to the inside barrel wall.

· Eurostyle rectangle barrel, reflux refrigeration is optimized and disposed, which makes temperature difference in C areas smaller.

· According to the material and special techinics demands, the material of cylinder can use high quality nitrided steel, corrosion proof or antifriction with corresponding process.

Screw element

The screw elements and then kneading blocks are designed accurately, by precise processed, agile combination, with interchangeability, which can fulfill efficient self-cleaning, transmission, compounding, pressure-forming.

· The screw material is made of high tool steel 38CrMoALA or W6Mo5Cr4V2 by special heat-treament.

Different types of screw elements can be used in a twin screw extruder. Generally there are four major types of screw elements, namely conveying elements, kneading elements, backward-pumping elements and mixing elements. For each type there are many different sub-types.