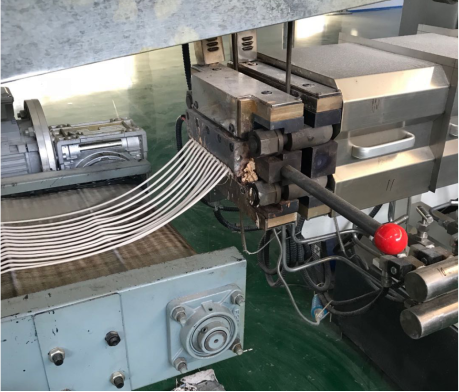

Air-cooling strand pelletizing line

Suitable for material with high filling masterbatch, starch degradation material, etc

A. For high filler masterbatch :PE/PP/EVA, + Caco3, Tio2, talc, carbon black, etc.

B. is used for fiber reinforced: PP/PA/PBT/ABS/AS/POM/PPS/PET/PC + glass fiber, carbon black;

PE = 85% Caco3.Including high-speed mixer for mixing PE+85% Caco3+ addiction;Screw loader for material loading;Extruder;Air-cooled hot surface cutting granulator tube for cooling and cutting;

PP + 70% Caco3.High-speed mixer for mixing PE® Caco3+ addictive agent;A screw loader for loading materials and an extruder for extruding;Water ring hot surface cutting granulation line, used for cooling and granulation;

Glass fiber reinforced: PP/PA/PA66/PA6+ glass fiber, with lateral feed

Air-cooling hot face pelletizing system

Air cooling hot face pelletizing systems could be applied to processing of some polymers, including PVC、LLDPE MB ,highly filled Calcium Carbonate MB, degradable MB, LSFH, carbon black MB ,cross-linkable PE ,Air cooling hot face pelletizing systems could avoid the moisture involved during pelletization process with replacing of air cooling .The main components usually include extrusion die plates, pelletizer, cyclone cooler and conveying units ,shifter ,silo and package units.

Water-ring pelletizing system

Water ring hot face die pelletizing systems could be applied to some polymers,including PE、PP、PS、TPU、EVA ect.The main components include extrusion plate,pelletizer,water circulating dewater,silo and package system.

Under water strand pelletizing line

The guide device is a vertically installed underwater granulator for granulating GPPS, HIPS, ABS, SAN, PMMA, PET, PA66 and other plastics. It can also granulate other kinds of polymers according to the special requirements of users.

1. Continuous and intermittent granulating production lines are applicable

2. Automatic feeding function

3. Cutting device can be replaced quickly without tools

4. Sensitive and reliable guide device anti-stacking monitoring mode

5. Compact structure saves space

6. The whole cooling section is equipped with grooves, effectively avoiding striping

7. The length of cooling section can be designed according to material characteristics

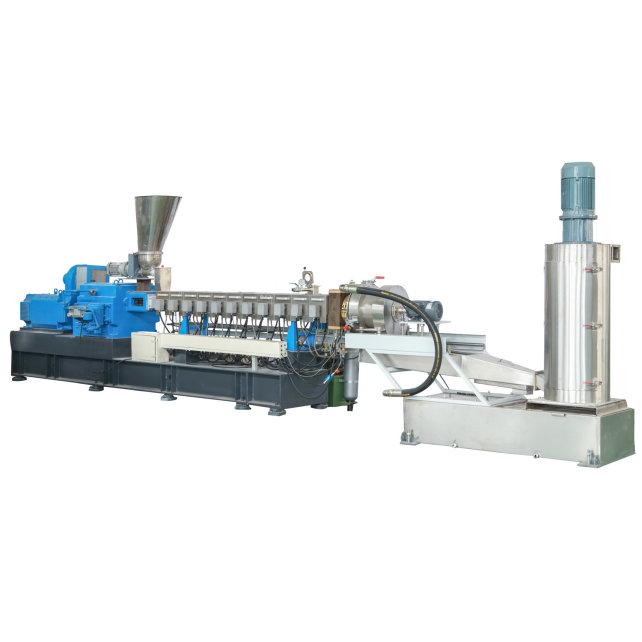

Water cooling strand pelletizing system

The system can be applied in most polymer materials processing, the whole system is simple and practical, and the operation and maintenance is convenient. The main components usually include: extruder orifice formwork, cooling tank, dryer, cold granulator, vibrating screen and follow-up bin packaging system, etc.

Can be used for:

1) Glass-filled reinforcement: PP, PA, PC, ABS, PET+up to 50% glass fibre reinforcing

2) High quality polymer alloys: PC+ABS, PA+ABS, PP+EPDM, PP +SBS

3) Color Masterbatch :PP, PE, PS, PBT, PET, ABS,EVA + COLOR PIGMENT

4) Special Master batch

5) Incorporation of fillers

PP, PA, PC, ABS, PPS, PET, PBT + up to 80% Calcium carbonate /Talc.

6) Compounds for cable and other pelletizing

7) Degassing extrusion

8) PET scraps recycling